Are Automated Valves Worth the Cost for Pool Systems?

Published on: December 17, 2025 | Last Updated: November 17, 2025

Written By: Rachael Weatherbottom

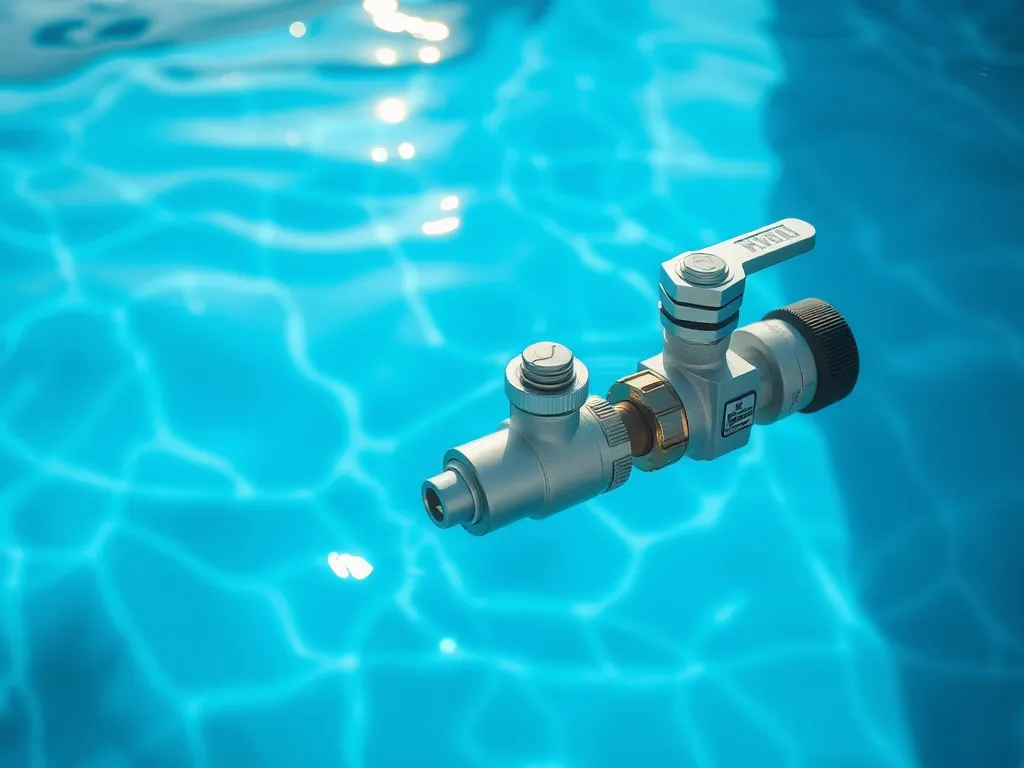

Automated valves for pools—motorized devices that control water flow through pipes using sensors or timers—can save up to 30% on energy bills and reduce manual labor, but their upfront cost ($300-$800 per valve) is 3-5x higher than manual valves ($50-$200). These valves adjust water direction automatically for features like spas, waterfalls, or cleaning cycles, balancing higher initial investments with long-term efficiency gains and convenience.

This article breaks down how automated valves work with pumps, heaters, and saltwater systems to cut costs. You’ll learn why valve sizing (1.5” to 3” diameters) impacts performance, how actuators sync with smart controls like Pentair IntelliCenter, and why improper installation can spike labor fees by $150-$400. We compare lifespan data—automated valves last 5-10 years versus 10-15 for manual models—and reveal how they prevent water waste during backwashing.

Explore real-world scenarios: A 20,000-gallon pool using automated valves saved $480/year on chemicals and energy. We’ll analyze payback periods (2-4 years for most systems), troubleshoot common failures like stuck diverter seals, and share pro tips for integrating valves with variable-speed pumps. Ready to see if automation fits your budget? Let’s dive into the numbers.

What Are Automated Valves for Pool Systems?

Automated valves for pool systems are motorized devices designed to control water flow between pool equipment and features without manual adjustments. These components serve as traffic directors for your pool’s plumbing, managing where water travels—whether to heaters, cleaners, spas, or water features—based on programmed settings or real-time demands. Properly functioning valves ensure that your swimming pool operates efficiently. This efficiency is key to maintaining clear and inviting water for enjoyment.

Crucial Winterizing Products

"The all-in-one solution for a guaranteed clear spring opening."

All-in-One Closing Chemical Kit

Winter demand is high - check stock

"The 'set & forget' option. This is the easiest winterizing I've ever done."

Simple 3-in-1 Winterizing Balls

Winter demand is high - check stock

"Invest once to protect your liner and prevent a swamp in the spring."

Heavy-Duty Winter Pool Cover

Winter demand is high - check stock

Definition and Core Functions

At their core, automated valves regulate three primary tasks: directing water flow paths, adjusting flow rates, and integrating with timers or sensors. They work by rotating internal gates (called diverter flaps) to open, close, or split water between plumbing lines. For example, a valve might shift flow from the pool’s main drain to a waterfall feature at scheduled times or when triggered by a remote control. This precision reduces energy waste, balances chemical distribution, and prevents equipment strain.

Types Of Automated Pool Valves

Two main categories dominate the market: 2-way valves (which fully open or close a single line) and 3-way valves (which split flow between two lines). Brands like Jandy and Pentair offer specialized models, such as the Jandy NeverLube or Pentair Compool valves, which are built to handle chlorinated water and resist corrosion. Diverter valves, commonly used for spas or solar heaters, can redirect 100% of flow, while check valves prevent backflow into sensitive equipment like heat pumps.

Actuators vs. Control Panels

| Component | Role | Cost Range |

|---|---|---|

| Actuators | Motorized units mounted directly on valves to physically turn them | $150–$400 per unit |

| Control Panels | Centralized systems (e.g., Pentair IntelliCenter) that send signals to actuators based on schedules or sensor data | $500–$2,500+ |

Costs vary by brand, voltage (24V vs. 120V), and smart features like Wi-Fi connectivity. Actuators handle the mechanical work, while control panels manage logic—both are needed for full automation. Bundled systems can lower per-unit pricing by 10–20% compared to buying parts separately.

Grasping these components sets the stage for analyzing whether their upfront price aligns with long-term gains. Let’s break down the numbers.

Evaluating the Cost Of Automated Pool Valves

Determining whether automated valves fit your budget starts with analyzing initial investments against potential savings. These systems range in complexity, making pricing variables critical to assess before committing.

Upfront Purchase and Installation Costs

Basic automated valve kits start at $200, while high-end models with smart connectivity or corrosion-resistant materials can exceed $800. Installation fees add $150–$500 depending on system integration with existing setups like pumps, heaters, or saltwater chlorinators. Multi-valve configurations for pools with spas or water features require more actuators, increasing total costs by 30–50%.

Factors Influencing Valve Sizing and Pricing

Valve size depends on pipe diameter—common sizes include 1.5″, 2″, and 3″—with prices rising $50–$150 per inch. Material choices also matter: PVC valves cost 20–40% less than brass but last 5–7 years versus 10–15. Weatherproof actuators rated IP68 or NEMA 4X add $75–$200 per unit but prevent moisture damage in humid environments.

Cost Comparison: Automated Vs. Manual Valves

Manual valves cost $50–$150 initially but lack automation capabilities. For example, a three-way manual valve averages $90, while its automated counterpart runs $300–$450. Though pricier upfront, automated models eliminate daily manual adjustments, saving 5–7 hours of labor monthly.

Long-Term Labor Savings

Automated valves reduce pool service visits by 60–80%, cutting annual maintenance fees by $400–$1,200. Homeowners handling their own care save 30 minutes weekly adjusting flow rates or switching between pool and spa modes—time adds up to 26 hours yearly. With labor rates at $75–$100/hour in many regions, these minutes translate into measurable annual savings. This efficiency can positively impact the overall cost of owning a small inground pool. When considering the budget for installation and ongoing care, understanding these savings is essential for homeowners.

Key Benefits Of Automated Pool Valves

Beyond dollars, automated valves improve pool management through precision and adaptability. These systems address common pain points like energy waste, chemical imbalance, and repetitive tasks. With better control, pool owners can achieve a cleaner and clearer water experience. This clarity is akin to looking into a deep pool, where every detail beneath the surface is visible.

Energy Efficiency and Cost Savings

By syncing with variable-speed pumps, automated valves reduce pump runtime by 25–40%. For a 1.5 HP pump running 8 hours daily at $0.15/kWh, this trims $15–$25 monthly off energy bills. Smart models with scheduling features can lower costs further by aligning cycles with off-peak electricity rates. Keeping pool chemicals effective is also important for overall maintenance. It’s good to know whether pool chemicals can expire and how this affects their performance.

Reduced Water Waste and Chemical Usage

Precise flow control minimizes backwashing frequency, saving 500–1,000 gallons monthly. Automated chemical feeders paired with valves maintain pH levels within 0.2 increments, reducing chlorine overuse by 15–20%. For pools using 2–4 gallons of liquid chlorine weekly, this equals $100–$200 yearly savings. Efficient use of chemicals is important for overall pool health. Adding a phosphate remover can help keep the pool water clear and clean.

Simplified Pool Maintenance

Programmable schedules handle tasks like draining spa overflow or activating cleaner lines automatically. Integration with platforms like Pentair IntelliCenter or Hayward OmniLogic allows remote adjustments via smartphone apps, eliminating manual valve turns during filter cleans or heater startups.

Enhanced Control Over Pool Features

Multi-zone setups let users direct water flow to specific areas—like waterfalls or solar heaters—with a tap. During parties, switching from spa jets to pool mode takes seconds instead of minutes. Advanced systems even adjust flow rates based on real-time pressure sensors, preventing pump strain. However, some people may wonder if drinking pool water is safe. While it is often treated with chemicals, it’s generally not advisable to drink it.

While upfront costs may give pause, the combined efficiency and convenience benefits position automated valves as a transformative upgrade. Next, let’s examine how these systems stack up against manual alternatives in day-to-day use.

Also See: Can You Run Pool Pump With Cover on? Here’s What to Know

Automated Valves Vs. Manual Valves: Which is Better?

Pool owners choosing between manual and automated valves must weigh daily functionality against long-term gains. Both options manage water flow, but differ in how much physical work and ongoing oversight they demand.

Operational Convenience Comparison

Manual valves require turning handles or levers to switch between pool features like spas, waterfalls, or cleaning modes. This can involve walking to equipment pads multiple times daily. Automated valves, powered by actuators linked to control panels, let users redirect water flow with a button press on a phone app or poolside interface. For multi-zone setups or frequent feature changes, automation cuts physical labor by up to 90%.

Cost-benefit Analysis Over Time

While manual valves cost $50-$200 each, automated versions range from $300-$800 per valve plus $200-$500 for installation. Initial outlay might seem steep, but labor savings add up. A pool service charging $100/hour for valve adjustments could cost $600 annually for manual systems. Over 5 years, automated valves often offset their higher upfront price by eliminating recurring labor fees.

Energy Efficiency and Automated Valves

Automated valves work with pool pumps and timers to optimize flow rates, directly impacting power bills. By syncing valve positions with pump schedules, they avoid pushing water through closed lines—a common source of wasted energy.

How Automated Valves Optimize Pump Usage

When set to “pool mode,” automated valves shut off spa jets automatically, letting pumps focus on main filtration. This reduces pump runtime by 25-30% without sacrificing water clarity. Smart systems can also prioritize solar heating loops or water features during off-peak utility hours.

Quantifiable Energy Savings

Data from Hayward and Pentair systems show automated valves trim 2-4 hours off daily pump operation. For a 1.5HP pump drawing 1,600 watts, cutting 3 hours daily saves 1,752 kWh yearly—about $263 at $0.15/kWh. Over a decade, this adds up to $2,630, often surpassing the valve system’s initial cost.

Reliability and Lifespan Considerations

Durability impacts total ownership costs. While manual valves rarely fail mechanically, their plastic components degrade with UV exposure. Automated systems add moving parts but build in safeguards against common issues.

Average Lifespan Of Automated Valves

Quality actuators from brands like Jandy or Polaris last 5-10 years. Stainless steel shafts and brass bodies resist corrosion better than manual valves’ PVC parts. Many include 3-year warranties, doubling typical manual valve coverage.

Common Maintenance Requirements

- Lubricating o-rings annually with silicone grease ($10/tube)

- Checking for debris in valve chambers during filter cleanings

- Updating control panel firmware to prevent software glitches

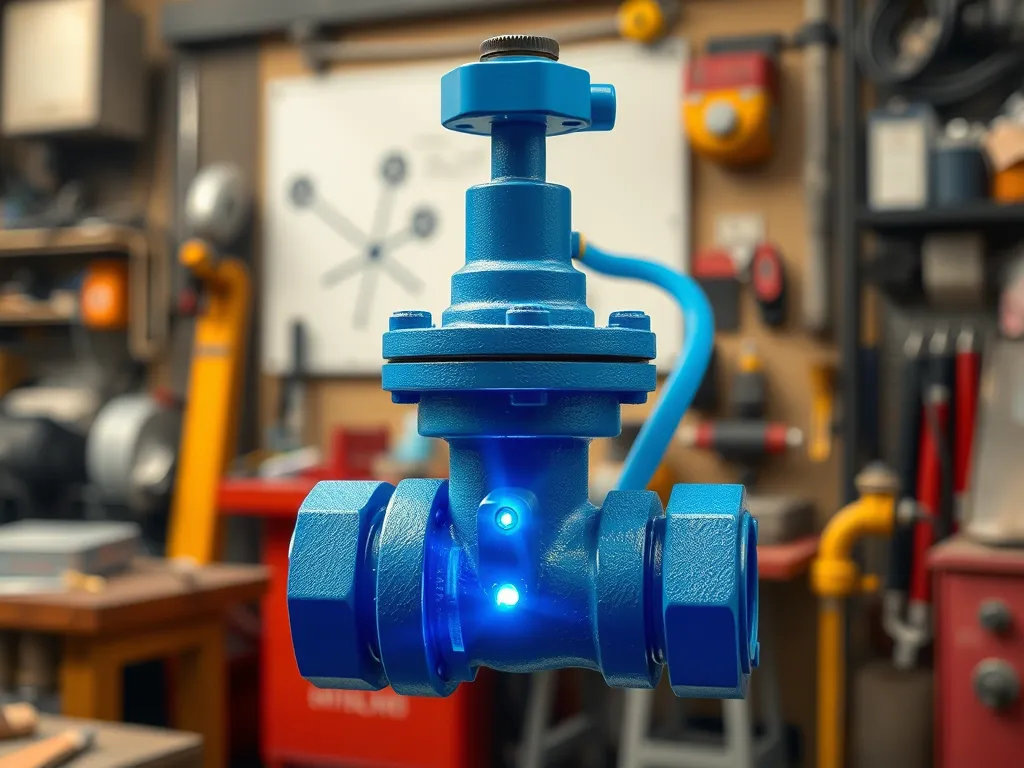

Diagnosing Valve Failures

If a valve stops responding, first verify power to the actuator (LED lights should glow). Listen for humming—a stuck internal gear might need manual override. Many systems flag error codes like “VALV 12” indicating positioning sensor faults, simplifying repairs.

With upfront costs and long-term gains clarified, pool owners should also factor in setup logistics. Proper installation ensures valves deliver on their promises.

Installation and Operational Best Practices

Proper setup of automated valves for pool systems directly impacts performance, longevity, and return on investment. Choosing the right installation method and ensuring seamless integration with existing equipment prevents operational hiccups that could negate cost savings. An efficient pool system starts with well-installed components. This ensures that pool vacuums can work effectively to keep the water clean and clear.

Professional Vs. DIY Installation

Automated pool valves require precise alignment with plumbing lines, electrical connections to control panels, and calibration for flow rates. Professional installers typically charge $150-$400 per valve, including labor, PVC fittings, and programming. This ensures proper actuator torque (measured in inch-pounds) matches pipe diameter – critical for valves handling 40-80 GPM flow rates common in residential pools. When considering these costs, it’s important to think about the overall expense of maintaining your pool. The cost of heating your pool can add significantly to your budget, especially if you want to keep it comfortable year-round.

DIY installations may save 30-50% upfront but risk leaks from improper solvent welding or motor burnout due to voltage mismatches. Most actuators operate on 24V AC, but older pools may have 120V lines requiring step-down transformers. Incorrect wiring can void warranties from brands like Jandy or Pentair. For complex setups with solar heaters or waterfall features, professional installation minimizes troubleshooting time.

Integration With Existing Pool Systems

Modern automated valves for pools connect to smart controllers like Hayward OmniLogic or IntelliCenter via RS-485 communication protocols. This allows synchronized operation with variable-speed pumps, salt chlorinators, and heater systems. For example, a 3-port valve actuator can automatically divert water to a spa while adjusting the heat pump’s setpoint. In relation to competition pools, these systems can help maintain precise water temperatures and flow rates. This ensures optimal conditions for competitive events, enhancing performance for swimmers.

- Retrofit Compatibility: Most actuators fit standard 2.5″ or 3″ diverter valves. Check flange patterns match existing valve tops

- Control Options: Use relay modules to link valves with timers, touchscreens, or Wi-Fi apps for remote scheduling

- Flow Optimization: Program valves to restrict flow to unused features, reducing pump energy use by 15-20%

For saltwater pools, ensure valve materials withstand corrosion. Brass or stainless-steel shafts paired with CPVC bodies handle chlorine levels up to 4,000 ppm better than standard polymers. As pool technology advances, smart pool technologies can monitor and adjust water chemistry automatically. These smart pool technologies help maintain optimal conditions and enhance the overall swimming experience.

With installation and integration handled correctly, automated valves become the backbone of an efficient pool system. Next, we’ll address common concerns about maintenance and troubleshooting to maximize your investment. Keeping your pool safe is just as important as maintaining its efficiency. A pool alarm can help alert you to any unexpected entries, adding an extra layer of security for peace of mind.

Frequently Asked Questions

Can Automated Valves Work With Older Pool Equipment?

Yes, most automated valves are compatible with older systems. Retrofit kits and universal actuators (e.g., Jandy 4724 or Pentair 263043) can adapt to pipes installed before 2010. Ensure your control panel supports 24V compatibility for seamless integration.

Do Automated Valves Require a Smart Home System to Function?

No—basic models operate via standalone timers or wired controllers. However, smart systems like Hayward OmniLogic enable advanced features like voice control and remote scheduling via iOS/Android apps.

How Do I Troubleshoot an Automated Valve That Isn’t Responding?

First, check power supply to the actuator and reset the breaker. Inspect for debris blocking the valve’s rotation and verify control panel programming. If the LED status light blinks red, consult the manual for error codes (e.g., Pentair’s “VALV 12” indicates a positioning fault).

Are Automated Valves Weatherproof?

High-quality actuators meet IP68 or NEMA 4X ratings, protecting against rain and pool splashes. For harsh climates, consider stainless steel models like the Zodiac JVA2444, rated for -40°F to 140°F operation.

What Warranties Are Available for Automated Pool Valves?

Most brands offer 2-3 year warranties. Pentair’s IntelliValve has a 3-year coverage, while Hayward Valves extend to 2 years. Extended warranties (up to 5 years) are often available for commercial-grade actuators. When considering starting a pool cleaning business, knowing about warranties can help you choose reliable equipment. This knowledge can also position your service as trustworthy and well-informed to potential clients.

Closing Thoughts

Automated valves bring precision and efficiency to pool systems, offering measurable savings in energy, water, and chemicals. While the initial investment ranges from $200 to $800 per valve, the long-term payoff in reduced labor and optimized performance often justifies the cost for frequent pool users.

For those with complex setups—multi-feature pools, saltwater systems, or smart home integration—automation is a game-changer. Manual valves remain viable for smaller, low-maintenance pools where hands-on control isn’t burdensome.

Explore My Pool Calculator to compare valve options, estimate ROI, and tailor solutions to your pool’s specific needs. The right choice balances upfront costs with the luxury of effortless control.

Additional Resources for You:

- Pool & Hot Tub Alliance (PHTA) – Industry Standards & Training

- r/homeautomation on Reddit: Smart controller for pool valves?

- Looking for a cheap way to automate my pool valves for cleaner and spa | Trouble Free Pool

- Should I Get an Automation System for My Pool?

- r/pools on Reddit: Looking for a cheap way to automate my pool valves for cleaner and spa

A pool care geek who’s been testing water chemistry since she was tall enough to reach the skimmer.

Pool Equipment Repair, Valves